Pneumatics opens up a world of possibilities when it comes to robotics. You could write a book on applications of pneumatics but for now we will start with the basics. Knowing what you need is sometimes harder than knowing how it works. For this example we are going to control an air cylinder extend and return slowly. We will be using a switch to turn on a solenoid valve and exhaust valves to control the speed that the cylinder extends and retracts.

Let’s start by reviewing the parts that we need:

- A double acting solenoid. This is the part of the setup that probably the most non-trivial. This is the valve that directs the air flow from the air tank to the cylinder. It has to be a double acting solenoid to make the cylinder drive in and out. It has a 12 volt coil so when power is applied it pulls in a plunger and allows air to flow. When power is turned off the plunger is released and reverses the flow of air. If you use a single acting solenoid it would only make the cylinder push in one direction.

- A double acting air cylinder. The size of the cylinder can be as large or as small as you need, but the basic concept is the same. Air goes in one side and out the other, pushing the cylinder rod in or out. A single acting cylinder has an input (pressure) and an exhaust. The cylinder we have shown is a double acting (has two ports that pressure can be applied).

- Air Supply and Air reservoir. This is an air compressor and a tank. We are using an industrial air compressor in our shop, but you can achieve the same result using a bicycle pump and an air tank.

- Exhaust Valves. These are not essential but they help control the speed of the cylinders. By limiting the amount of air being exhausted you can control the speed of the cylinder. There are many types of exhaust valves but we are using is exhaust needle valves. These allow us to adjust the size of the air orifice, allowing us to control the flow of the air and therefore regulating the speed the cylinder moves.

- Fittings. There are hundreds to choose from. We like using push-to-connect fittings. They are simple to size, reliable, and easily reusable.

- Tubing. The tubing we use matches the push-to-connect fittings. We happen to be using 5/32 inch tube and it works well for our purposes.

- Pressure switch/relief valve. This is for your own protection. The pressure switch is sometimes built into an air compressor (like the kind from Home Depot or Lowes Home Improvement Stores). It shuts the compressor off when a certain pressure is reached to keep it from over-pressurizing. A relief valve is used on the air tank. This is a valve that is meant to “fail” to an open position if the pressure gets too high. It is analogous to a fuse in an electrical system.

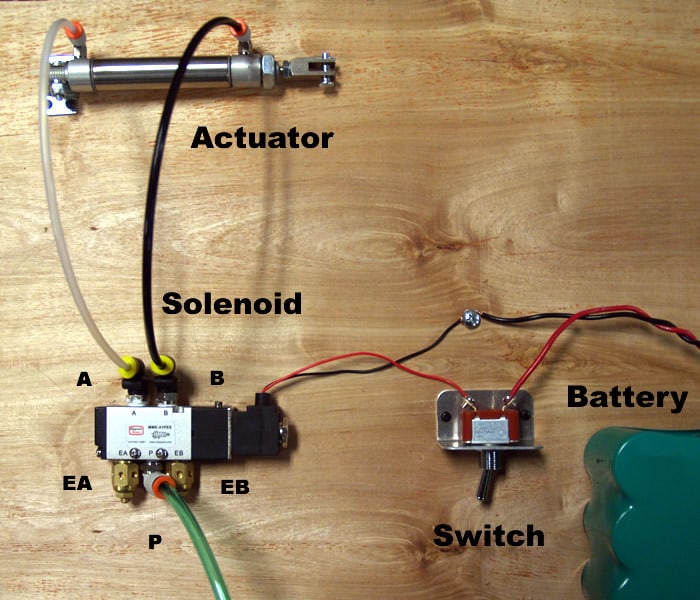

The figure above shows a typical setup. You can see the double acting cylinder, double acting solenoid, needle exhaust valves, push to connect fittings and tubing, switch and battery. The green tube comes from our air compressor. It has a built-in pressure switch and safety pop-off relief valve.

When power is applied to the solenoid, a plunger moves and directs the air pressure out of port A. The same movement opens port EB. EB is the exhaust for the air that is already in the cylinder. By using a needle exhaust valve you can limit the amount of air that is being let out. You can open it all the way and the cylinder will move very fast, or close (tighten) it all the way and make the cylinder slowly bleed down.

When you turn the power off to the solenoid, the plunger springs back into its off position, which directs the airflow out of port B and into the opposite side of the air cylinder. Port EA is opened and the air that is in the bottom side of the cylinder is forced out the exhaust valve. Here again you can adjust the speed the cylinder moves back in by limiting the amount of air that is escaping through the exhaust.

So how is this useful? The possibilities are endless and pneumatic systems have been proven to be very reliable. Take a look at the picture below of our 1970s era Bridgeport Milling Machine. It uses an air cylinder to engage the brake when the spindle is turned off. Close to 50 years in service and it is still working flawlessly.

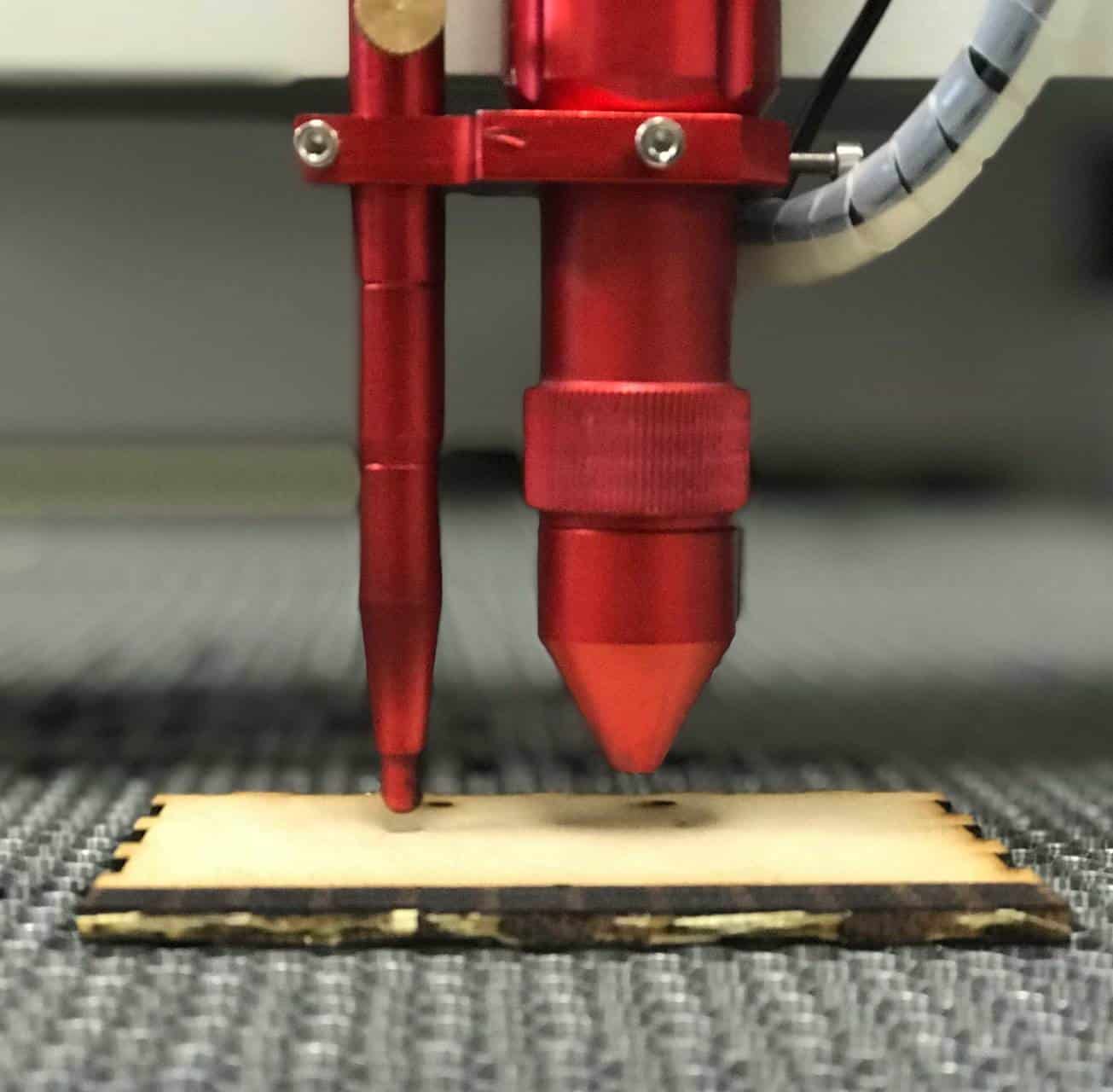

We also have a plasma machine built in 2013 that uses an air cylinder to engage a spur gear that drives the plasma torch.

One of our more recent projects in which we used an air cylinder was with a smoke generating gun mounted on our HD2 tank. We needed a quick acting, very high force to pull the trigger and the air cylinder did the job.